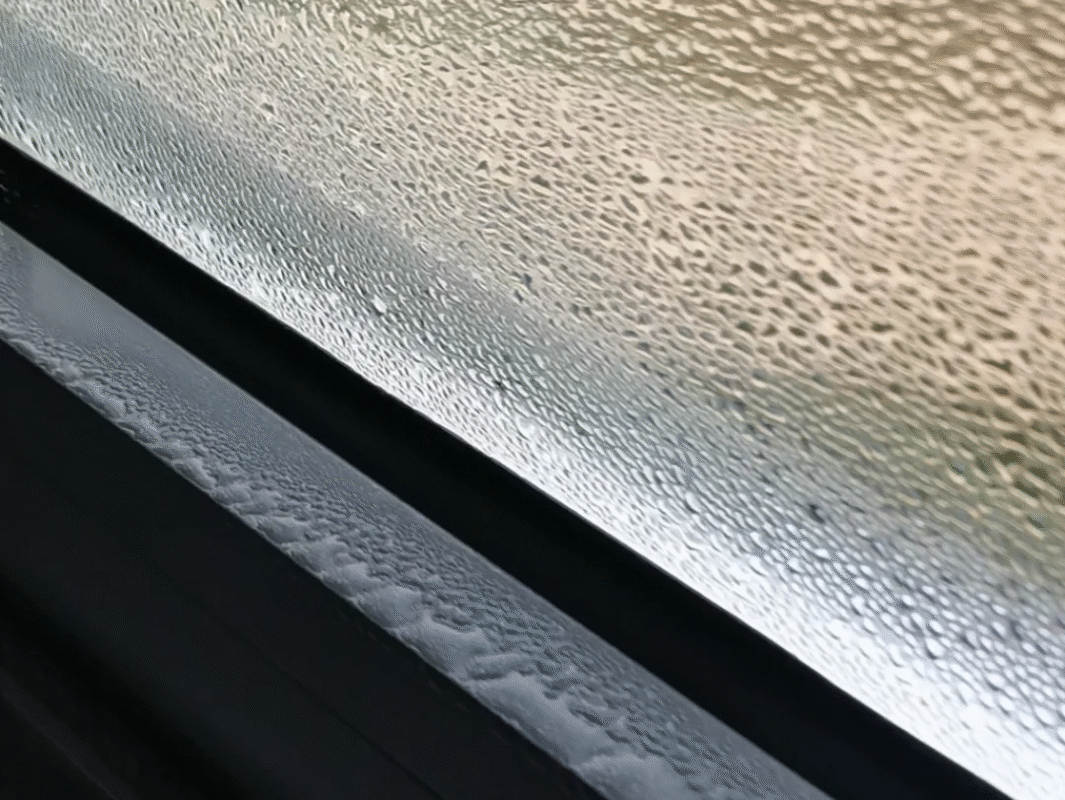

Wake up in the morning, and the window that should be filled with sunlight is covered with water droplets, even flowing down the glass to soak the windowsill; dark mold spots that can’t be wiped clean quietly spread in the corners of the window frame——this is a trouble for many families in winter. You might think this is caused by cold weather or high humidity, but in fact, frequent condensation and mold are warnings that your windows and doors are “underperforming”.

I. Why Do Windows Get Condensation & Mold in Winter? 3 Core Causes

The essence of window condensation and mold is: Windows and doors cannot effectively block heat exchange, leading to surface temperature lower than the dew point of indoor air, and mold grows after water vapor condenses. Specifically, the problems mainly lie in these 3 aspects:

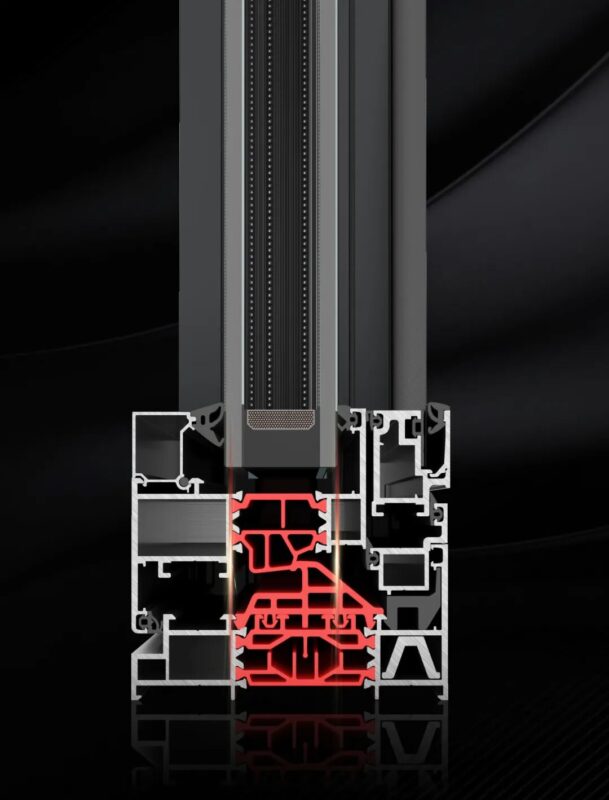

1. “Cold Bridge Effect” in Profiles: A “Highway” for Heat Loss

Traditional aluminum profiles are good conductors of heat, just like a “highway for heat loss”——warm indoor heat is quickly conducted to the cold outdoor through the profiles, resulting in extremely low temperature of the window frame, forming a “cold bridge”. And the cold bridge is where water vapor condenses first and condensation is most serious.

2. Poor Insulation of Glass: “Thin Clothes” Can’t Withstand the Cold Winter

Single glass or ordinary double-layer insulated glass has insufficient insulation performance (K-value). In winter, the inner surface temperature of the glass is much lower than the indoor air temperature. Once the indoor humidity is slightly high (such as after cooking or taking a bath), the glass will become a “water curtain cave”, and the long-term humid environment directly promotes mold growth.

3. Failed Sealing System: A “Channel” for Water Vapor to Enter and Exit Freely

Aged, hardened, or broken seal strips, or insufficient gap filling during installation, will cause tiny gaps between the sash and frame, and between the glass and profile. This not only allows cold air to enter, but also lets warm and humid indoor air “escape”, condensing directly into water on the cold surface of windows and doors, accelerating mold growth.

II. The Fundamental Solution: Install an “Anti-Condensation Immune System” for Windows

To completely solve condensation and mold problems, we can’t just rely on superficial methods like “wiping water droplets and removing mold”. The key is to choose windows and doors with systematic performance to eliminate the root causes:

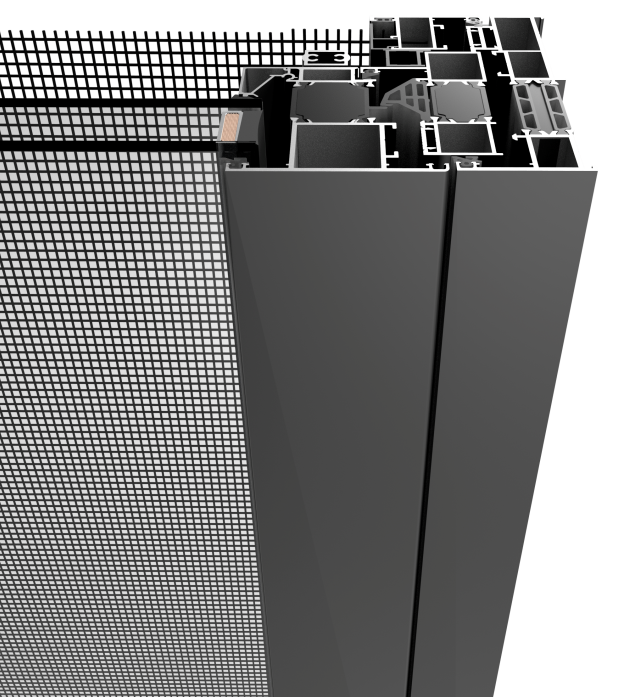

1. Multi-Chamber Broken Bridge Profiles: Core Defense Against Cold Bridges

Adopt multi-chamber broken bridge aluminum profiles, with PA66 nylon thermal barrier strips embedded in the aluminum profiles——like a solid “thermal insulation bridge”, directly cutting off the path of heat and cold transfer. At the same time, the interior of the profile is designed with multiple independent chambers to form an air barrier, slowing down heat loss, making the inner surface temperature of the window frame close to the indoor temperature, and eliminating cold bridge condensation from the root.

2. High-Performance Insulated Glass + Warm Edge Spacers: Keep Glass “Warm”

It is recommended to use triple-glazed double-insulated glass or double-glazed Low-E insulated glass:

- Low-E glass is coated with an extremely thin silver film, which can reflect the thermal radiation (far-infrared rays) of indoor heating back to the room like a mirror. Experiments have proved that it can increase the inner surface temperature of the glass by 3-5℃, greatly reducing the risk of condensation;

- Match with composite warm edge spacers (replacing traditional aluminum spacers) to improve the heat conduction at the edge of the glass, keeping the surrounding area of the glass warm and dry, and avoiding mold at the window corners.

3. Triple Sealing + Precision Installation: Prevent Water Vapor from “Sneaking In”

- Use EPDM automotive-grade foam seal strips to form three tightly interlocking sealing lines between the sash and frame, building a double barrier of air tightness and water tightness to prevent water vapor circulation;

- Follow the principle of “30% product, 70% installation”: fully fill the gap between the window frame and the wall with waterproof mortar or foaming agent, and apply weather-resistant sealant on the outside to integrate the window with the building wall, eliminating leakage and condensation caused by installation gaps.

III. Invest in Quality Windows, Gain a Healthy Home

The core cause of condensation and mold is that windows and doors cannot effectively block heat exchange. Choosing a set of system windows with multi-chamber broken bridge profiles, Low-E insulated glass, and triple sealing technology can not only completely solve the persistent problem of winter condensation and mold, but also improve indoor thermal insulation and reduce energy consumption.

iSuperhaus Windows & Doors focuses on high-performance window solutions. Its system window series integrates the above core technologies to build a real warm defense line for families. Say goodbye to winter window condensation and mold by choosing a set of high-quality windows that “can keep warm and seal tightly”.

Tip: If there are slight mold spots at home, you can first wipe them with a solution of white vinegar and baking soda. After drying, check the sealing and insulation performance of the windows and doors in time, and replace aging parts or upgrade the window system if necessary.